Recycle old modules

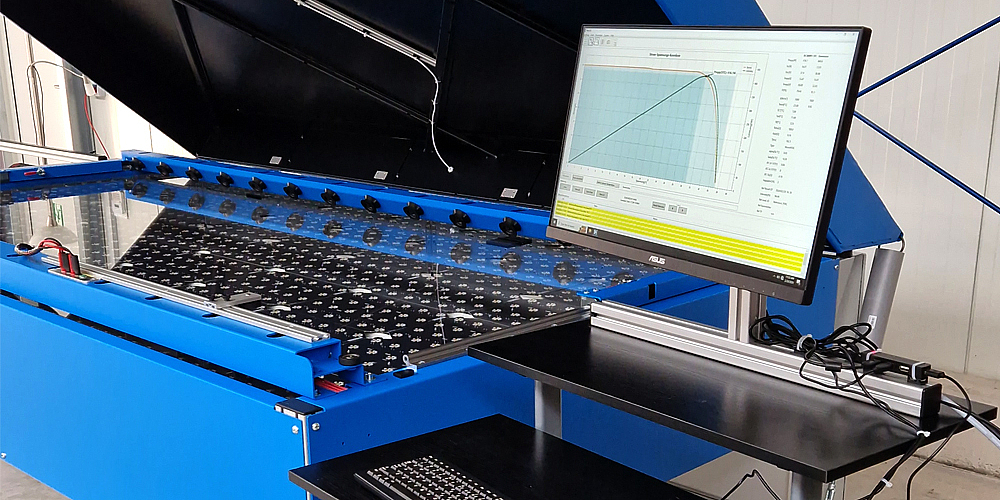

As an all-in-one solution, the MBJ Module Tester measures the most important criteria of a module. This allows a quick and cost-effective decision to be made as to whether a module can be reused or whether it needs to be disposed of properly.

Manual operation simplifies the system and leads to an enormous reduction in the product price. The system can inspect up to 120 modules per hour, with the user-friendly software supporting the operator in assessing the EL images and evaluating the data.

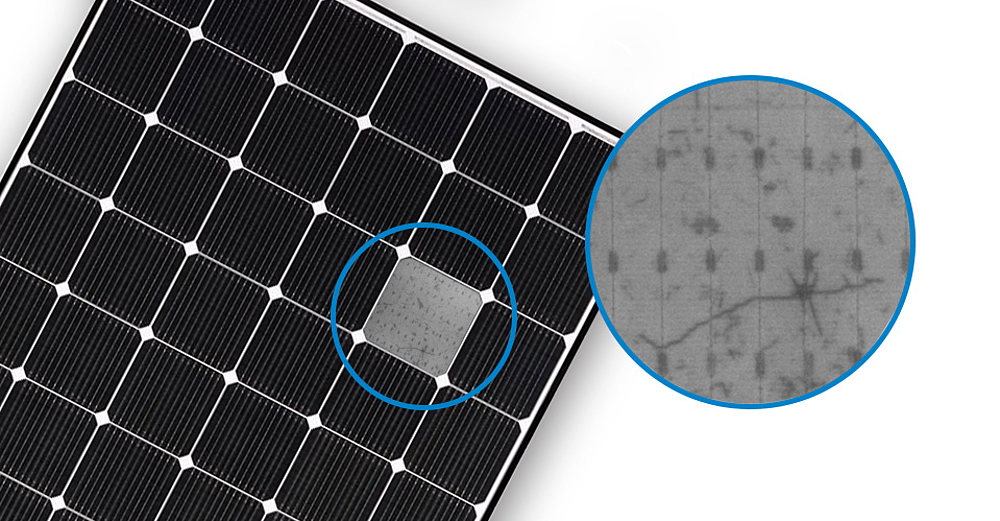

Proven Electroluminescence Technology

With the help of electroluminescence images critical defects such as microcracks and soldering defects are made visible in PV modules . This test improves overall product quality and it optimizes the production process. Electroluminescence testing is a standard in todays module manufacturing and indispensable in production. These systems are usually used before lamination as process control and at the end of the production line as output control for all modules produced.

The requirements for the electroluminescence test have steadily increased in the last years. Today, as example, cycle times of less than 20 sec are required. An automatic evaluation with a high-resolution system is therefore the standard. With more than 450 electroluminescent test systems installed worldwide, MBJ is the market leader in Europe, offering the right solution for all requirements.

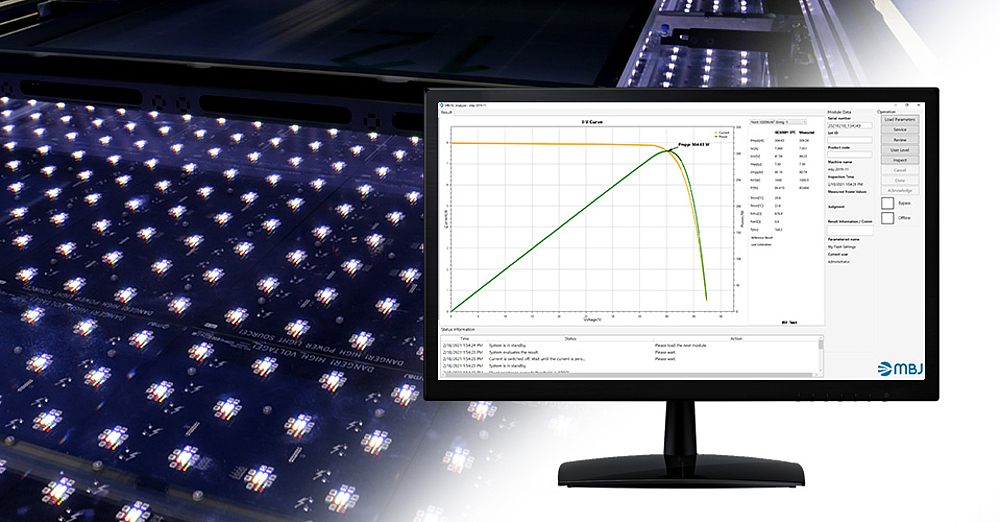

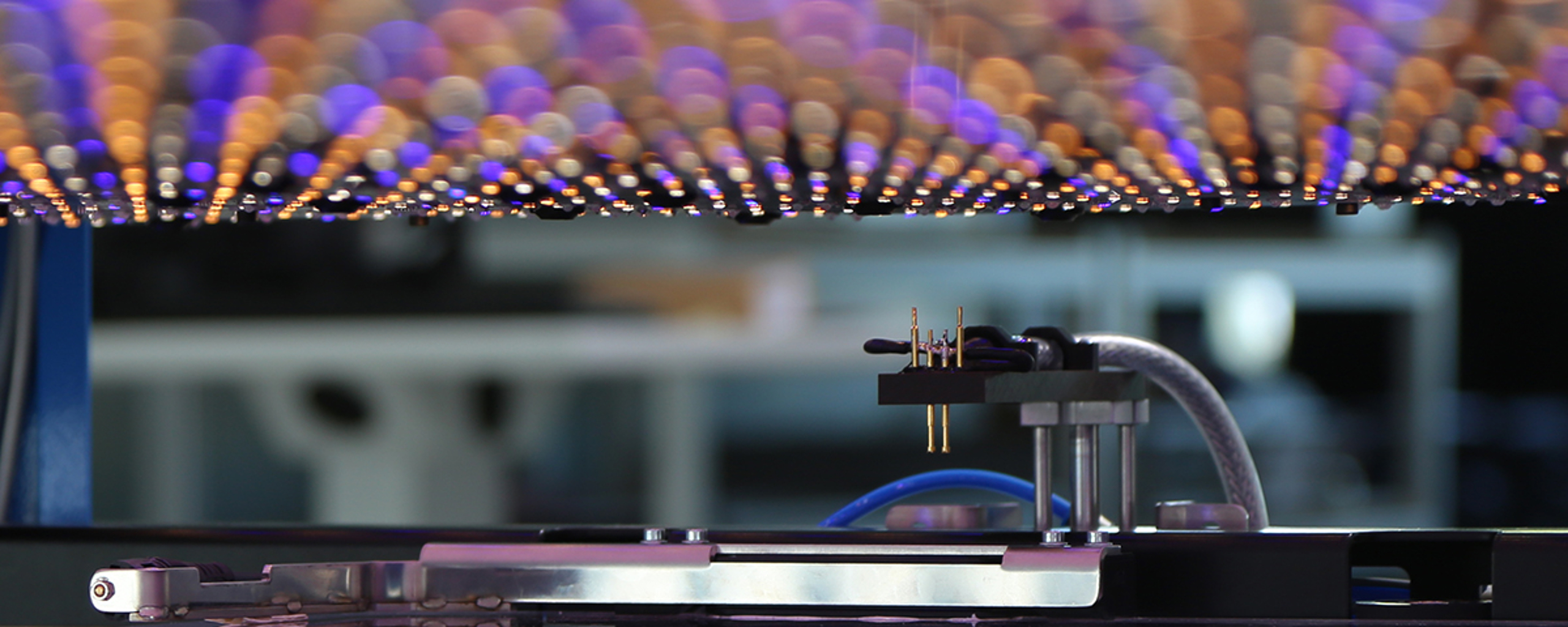

Innovative LED-Technologie

LED technology is the future. With our LED flashers a flash duration of up to 200ms can be realized without any problems, which is indispensable for new module concepts. The LEDs are designed for several million measurements, under normal conditions, replacement of the LEDs is no longer necessary. The light intensity and the spectrum also remain stable over the entire product life cycle.

The long life of the LEDs also leads to an immense cost savings compared to a xenon flasher. Another advantage of LED technology is that the individual LEDs or the groups of LEDs can be controlled very precisely. This control allows a nearly constant luminosity over the entire flash duration. The very good stability of the light source leads to an excellent reproducibility of the measurement results. Are you interested? Find out more about our LED solar simulators.

Why you can trust MBJ

Customer focus

The customer and his requirements are at the center of our thoughts and actions.

Individual solutions

We love technical challenges. Customized adjustments are part of our business. Contact us.

Innovation

We continuously improve our products and adapt them to the demands of the market.

Worldwide experience

Rely on our experience from more than 450 installed inspection systems worldwide.

![[Translate to english:] [Translate to english:]](/fileadmin/_processed_/0/2/csm_600x450px_NEWS_SOL-smartcon2_295489cf4d.jpg)

![[Translate to english:] MBJ Light soaking unit](/fileadmin/_processed_/d/b/csm_MBJ_Light_Soaking_geoeffnet_8a35cfb07b.jpg)

![[Translate to english:] MBJ MobileLab as Trailer or Transporter](/fileadmin/_processed_/9/f/csm_640x480-MBJ-mobilelab-trailer-and-transporter-72dpi_4b89e9c1b2.jpg)